Measure the relation between PWM Duty Cycle and Speed

%% 1. Create test data

maxPWM = 1.00; % Maximum duty cycle

incrPWM = 0.05; % PWM increment

PWMcmdRaw = (-maxPWM:incrPWM:maxPWM); % Column vector of duty cycles from -1 to 1

speedRaw = zeros(size(PWMcmdRaw)); % Initialize a vector for speed raw reads%% 2. Create and initialize device objects

clear a dcm carrier enc % Delete existing device objects

a = arduino;

carrier = motorCarrier(a);

dcm = dcmotor(carrier,'M1'); % Connect a DC motor at 'M1' port on the Arduino Nano Motor Carrier board

enc = rotaryEncoder(carrier,1); % Connect the encoder of 'M1' at the encoder port 1 on the Arduino Nano Motor Carrier boardColumn vector of duty cycles from -1 to 1%% 3. Measure raw motor speed for each PWM command

dcm.Speed = 0;

gearRatio = 100; % As per the motor spec sheet, gear ratio equals 100:1

start(dcm) % turn on motor

dcm.Speed = PWMcmdRaw(1); % this assigns the first value to dcm.Speed

pause(1) % wait for steady state

speedRaw(1) = readSpeed(enc)/gearRatio; % read motor speed in rpm of the output shaft

stop(dcm); % turn off motor

dcm.Speed = 0; After running this section, the DC motor will run at max speed (-1) for 1 second and stop. Array - speedRaw will record the encoder counter read.

To measure all possible values, we use for-loop:

%% 3. Measure raw motor speed for each PWM command

dcm.Speed = 0;

gearRatio = 100; % As per the motor spec sheet, gear ratio equals 100:1

start(dcm) % turn on motor

for ii = 1:length(PWMcmdRaw)

dcm.Speed = PWMcmdRaw(ii);

pause(1) % wait for steady state

speedRaw(ii) = readSpeed(enc)/gearRatio; % read motor speed in rpm of the output shaft

end

stop(dcm) % turn off motor

dcm.Speed = 0;Now visualize the result:

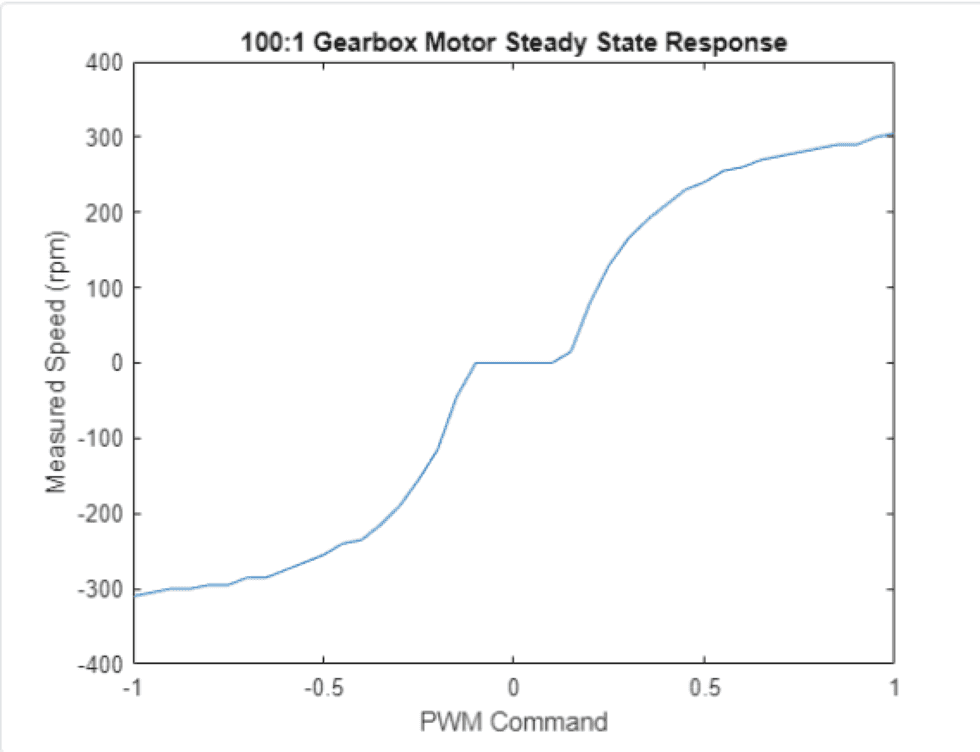

%% 4. Graph raw data

plot(PWMcmdRaw,speedRaw) % raw speed measurements

title('100:1 Gearbox Motor Steady State Response')

xlabel('PWM Command')

ylabel('Measured Speed (rpm)')Post-Process Speed Measurements to remove "Dead Zone"

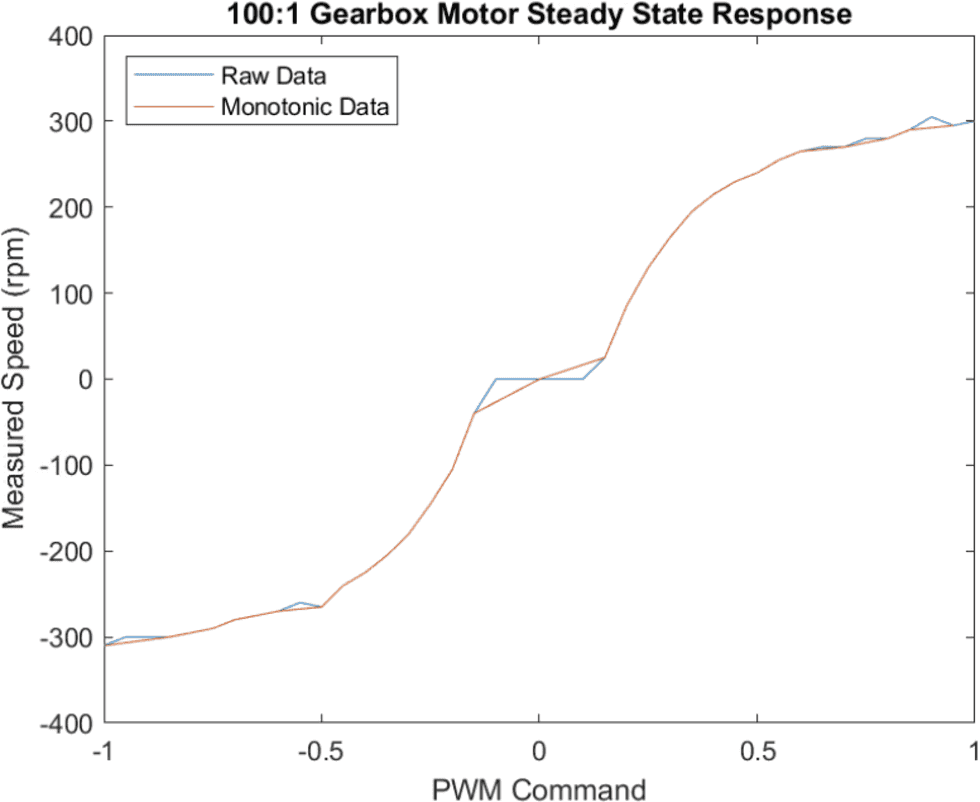

To create a motor control system, in which a user will request a motor speed in rpm and system gives the PWM duty value, we need to remove repeated values.

%% 5. Post-process and save data

idx = (diff(speedRaw) > 0) % speedRaw is 1x41 vector. diff calculates the

% difference between 2 consecutive values. idx

% is a 1x40 vector containing 1 and 0. 1 means at

% that index, the diff is not 0.

speedMono = speedRaw(idx); % speedMono is a sub-set of speedRaw with different

% values

PWMcmdMono = PWMcmdRaw(idx);

PWMcmdMono(speedMono == 0) = 0; % enforce zero power for zero speed

save motorResponse PWMcmdMono speedMono % save post-processed measurements%% 6. Graph raw and post-processed data

plot(PWMcmdRaw,speedRaw) % raw speed measurements

hold on

plot(PWMcmdMono,speedMono) % non-monotonic measurements filtered out

title('100:1 Gearbox Motor Steady State Response')

xlabel('PWM Command')

ylabel('Measured Speed (rpm)')

legend('Raw Data','Monotonic Data','Location','northwest')%% 6. Delete device objects

clear a dcm carrier encCreating Matlab Functions

By creating "live function", we can manage reusable functions by defining:

function [PWMcmdMono,speedMono] = myMotorFunction(PWMcmdRaw,dcm,enc)With the help of this function, section 3-6 can be replaced by one line of function call.

In the tutorial, to save data to work place, it uses

save(filename, 'vector-1', 'vector-2'). However, it looks like it does not work in my workplace. I need to change it tosave filename vector-1 vector-2.

With the file myMotorCharacterization.mlx and myMotorFunction.mlx, we can run clear then myMotorCharacterization in the command window to reuse the characterization funcion. PWMcmdMono and speedMono will be saved in motorResponse.mat file.